Showroom

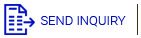

Our Cement Plants range includes grinders, kilns, and other machines that are beneficial in crushing stones, mixing construction materials and heating the produced items for rigidity, rust resistance and longevity.

Npk Npks Mix Blended Fertilizer Plants are provided with advanced functionality. Supplied are provided with different capacities and are used to blend urea, gypsum and ammonium chloride and many other materials.

Sugar Plants we deal in are used for manufacturing the sugar, on large scale. The plants ensure high productivity of sugar and work with an eco-friendly operation.

Single Super Phosphate TSP Plants are supplied with speedy and stress-free production of superphosphate. These can perform the reaction in a safe manner. Provided plants can work with several hours, without any trouble.

Phosphate is a substance that is beneficial for complete plant growth. For making such compounds, we provided Phosphate Plants that blend, purify and stabilize the chemical substance. The machines are rust safe, simple to run, and demands least to zero maintenance.

Our Chemical Plants comes with demanded safety instruments because they handle corrosive and explosive chemicals. They are huge and efficient to mix and separate compounds while stabilizing the harmful agents.

Our Fertilizer Machine can make different variants of fertilizer compounds and agents for large and medium crop fields. We also provide drums that are useful in stabilizing and mixing the substances at elevated speed and controlled temperatures.

Clinker Grinding Units are well-equipped with excellent quality feeding systems. These work with advanced accuracy due to the measuring systems these are available with.

In this category, we deliver Turnkey Plants that require huge space for installation. These come intact with required components, machines and parts that work together to provide greater output rate with an unmatched proficiency.

|

MEGATECH INTERNATIONAL PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |